Everything you need to know about the riso print process.

Meet the RISO

RISO is a low-cost, eco-friendly print process with a unique aesthetic. Invented in 80s Japan as a duplicator for schools and offices, RISO is now really popular with graphic designers, artists and illustrators.

We have two RISO models, an RZ370EP and a dual-drum MZ1090. Both are pre-loved, and over the years have clocked up a lot of mileage between them. They can be a little temperamental, but they’re still going strong!

Once each master is made, the machine can reproduce thousands of copies very quickly and cheaply. It’s best used for runs of 50+ prints, as most of the cost is in making the masters (extra prints cost pennies!)

How does it work?

Think of it as mechanical screenprinting. The machine makes a ‘master’ stencil of your artwork and wraps it around the ink drum. Ink is then pushed through the stencil onto the paper as the drum rotates at high speed. Want a two-colour print? Change the ink drum, make a new master and put the same paper through again for the second layer.

What can I use it for?

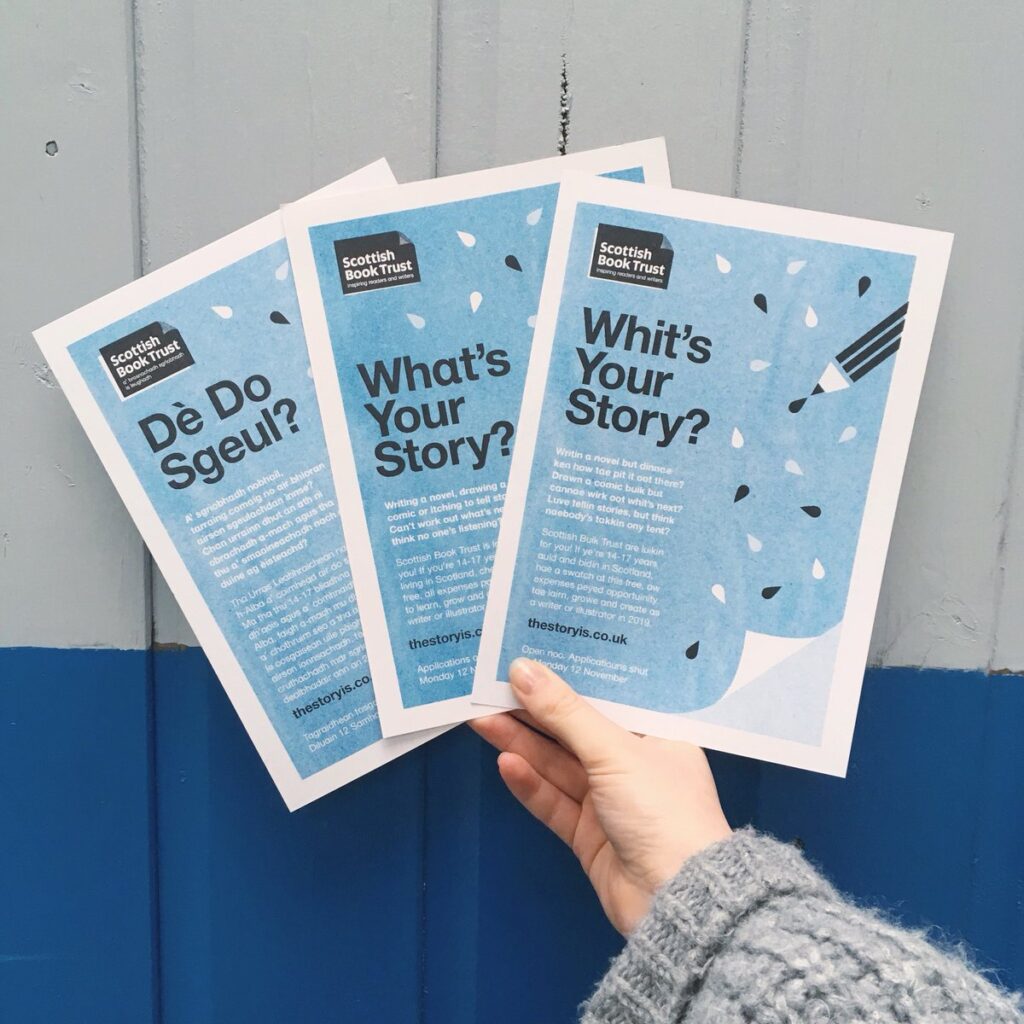

RISO isn’t like a normal full-colour printer, so it doesn’t work for glossy photos – but it’s perfect for flyers, posters, artwork, illustrations, comics, booklets, zines, indie mags, programmes, leaflets, you name it.

RISO is energy efficient, with no harmful emissions and minimal waste. Using inks derived from risk husks and banana paper stencils, we print on recycled paper stock and use local suppliers to reduce our impact on the environment.

It’s the most eco-friendly printer on the planet!

Ready to give it a try?

It’s easier than you think to create beautiful, unique riso prints.